Engineers at the University of California, Davis, have developed a new approach to 3D printing that allows printing of finely tuned flexible materials. By using a droplet-based, multiphase microfluidic system, the team was able to efficiently print materials with potential applications in soft robotics, tissue engineering and wearable technology. The work is published June 15 in the Proceedings of the National Academy of Sciences.

In traditional extrusion-based 3D printers, printing material is pushed through a nozzle and added to the structure repeatedly until the product is complete. While this is efficient and cost-effective, it makes it hard to print structures made of more than one material, and getting the right amount of softness can be challenging.

Jiandi Wan, assistant professor of chemical engineering at UC Davis, noticed that this nozzle was similar to the glass capillary microfluidic devices that his lab studies. These devices have multiple nozzles placed inside of each other.

“Most extrusion-based 3D printers use very simple nozzles and since we had already developed these glass microfluidics, we thought, ‘why not apply it to 3D printing?’” said Wan.

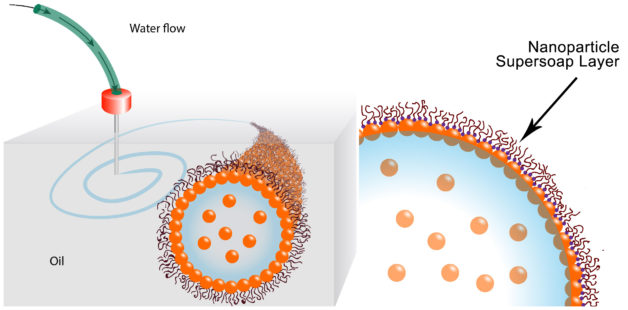

Wan, UC Davis graduate student Hing Jii Mea and Luis Delgadillo, University of Rochester, developed a device that uses a multiphase drip system to encapsulate droplets of a water-based solution containing polyethylene glycol diacrylate, or PEGDA, inside of a common silicon-based organic polymer called polydimethylsiloxane, or PDMS. The PDMS flows around a dripper, which makes tiny droplets of the PEGDA that it evenly inserts into the PDMS as both materials flow onto the structure that’s being printed.

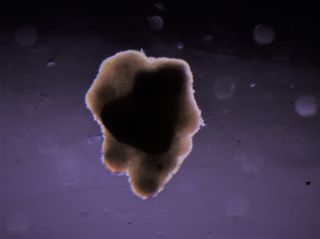

The resulting structure looks like a Pac-Man maze, with little dots of PEGDA droplets surrounded by PDMS. Once the PEGDA diffuses out of the droplets, it chemically softens the PDMS, making the structure more flexible.

“You can also encapsulate other chemicals in the droplets to make the overall matrix much softer or harder,” Wan said.

Structure flexibility can be tuned

The team also showed that droplet-based 3D printing can be used to produce flexible porous objects, and constructs with encapsulated polymer particles and metal droplets. In addition, structure flexibility can be easily tuned by changing the droplet size and flow rate. This gives researchers a wide range of options to truly design their structure and vary flexibility to fit their needs in a way that’s difficult with the conventional nozzle-based method.

Though microfluidic-based 3D printing has been done before, Wan’s group is the first to use this droplet-based multiphase emulsion approach. The team is already looking into potential applications and learning what other combinations of materials they can use to change the mechanical or chemical properties of 3D printed products. They think the work could have applications in bioprinting and wearable electronics, like smart fabrics.

“I think this will open a new area of research, since applying the established microfluidics technology to 3D printing represents a new direction to go,” he said.

Media contact(s)

Jiandi Wan, Chemical Engineering, jdwan@ucdavis.edu

Andy Fell, News and Media Relations, 530-752-4533, ahfell@ucdavis.edu

Media Resources

Source: New Technique Allows 3D Printing of Flexible Materials | UC Davis