Growing cartilage tissue in the lab could help patiens with injuries, but it is very hard to make the tissue grow in exactly the right shape. A new approach could solve this problem: Tiny spherical containers are created with a high-resolution 3D printer. These containers are then filled with cells and assembled into the desired shape. The cells from different containers connect, the container itself is degradable and eventually disappears.

[…]

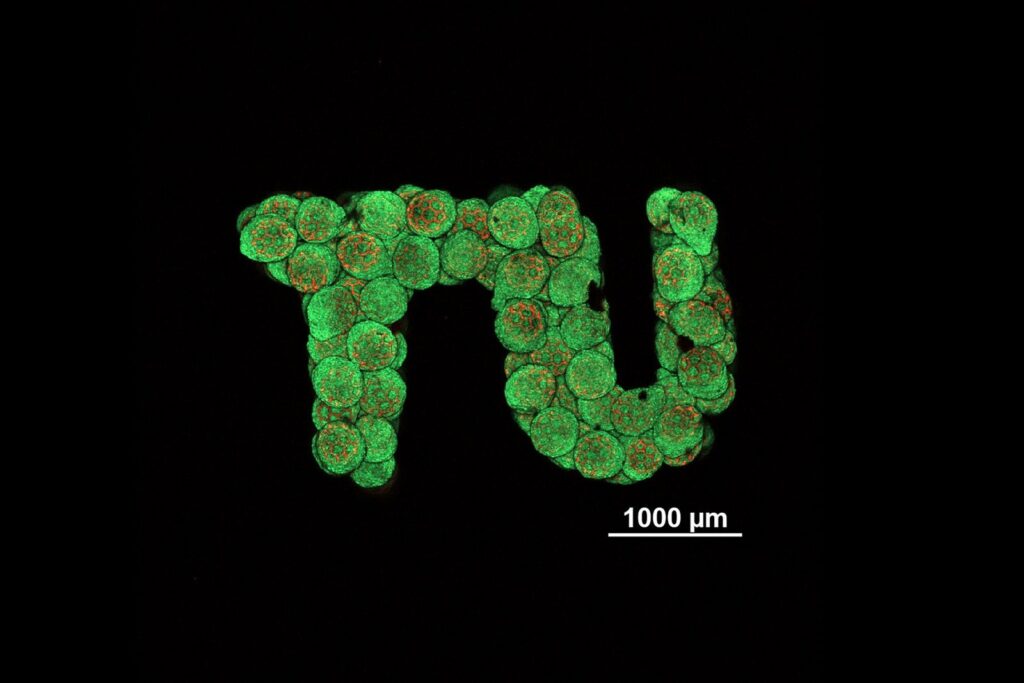

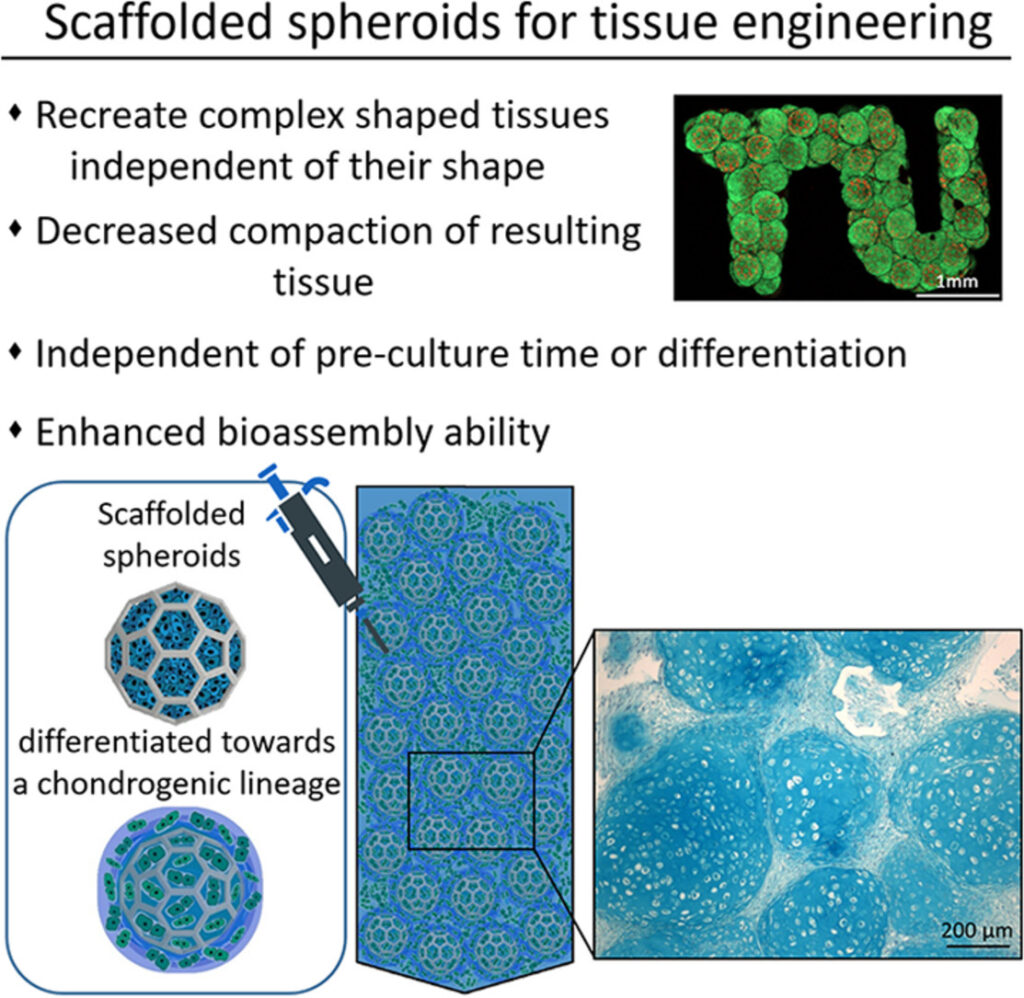

A special high-resolution 3D printing process is used to create tiny, porous spheres made of biocompatible and degradable plastic, which are then colonized with cells. These spheroids can then be arranged in any geometry, and the cells of the different units combine seamlessly to form a uniform, living tissue. Cartilage tissue, with which the concept has now been demonstrated at TU Wien, was previously considered particularly challenging in this respect.

Tiny spherical cages as a scaffold for the cells

“Cultivating cartilage cells from stem cells is not the biggest challenge. The main problem is that you usually have little control over the shape of the resulting tissue,”

[…]

To prevent this, the research team at TU Wien is working with a new approach: specially developed laser-based high-resolution 3D printing systems are used to create tiny cage-like structures that look like mini footballs and have a diameter of just a third of a millimeter. They serve as a support structure and form compact building blocks that can then be assembled into any shape.

Stem cells are first introduced into these football-shaped mini-cages, which quickly fill the tiny volume completely.

[…]

The team used differentiated stem cells — i.e. stem cells that can no longer develop into any type of tissue, but are already predetermined to form a specific type of tissue, in this case cartilage tissue.

[…]

The tiny 3D-printed scaffolds give the overall structure mechanical stability while the tissue continues to mature. Over a period of a few months, the plastic structures degrade, they simply disappear, leaving behind the finished tissue in the desired shape.

First step towards medical application

In principle, the new approach is not limited to cartilage tissue, it could also be used to tailor different kinds of larger tissues such as bone tissue. However, there are still a few tasks to be solved along the way — after all, unlike in cartilage tissue, blood vessels would also have to be incorporated for these tissues above a certain size.

“An initial goal would be to produce small, tailor-made pieces of cartilage tissue that can be inserted into existing cartilage material after an injury,” says Oliver Kopinski-Grünwald. “In any case, we have now been able to show that our method for producing cartilage tissue using spherical micro-scaffolds works in principle and has decisive advantages over other technologies.”

Source: Artificial cartilage with the help of 3D printing | ScienceDaily

Robin Edgar

Organisational Structures | Technology and Science | Military, IT and Lifestyle consultancy | Social, Broadcast & Cross Media | Flying aircraft