Back in 2013, Techdirt wrote about “the monster lurking inside free trade agreements”. Formally, the monster is known as Investor-State Dispute Settlement (ISDS), but here on Techdirt we call it “corporate sovereignty“, because that is what it is: a system of secret courts that effectively places companies above a government, by allowing them to sue a nation if the latter takes actions or brings in laws that might adversely affect their profits.

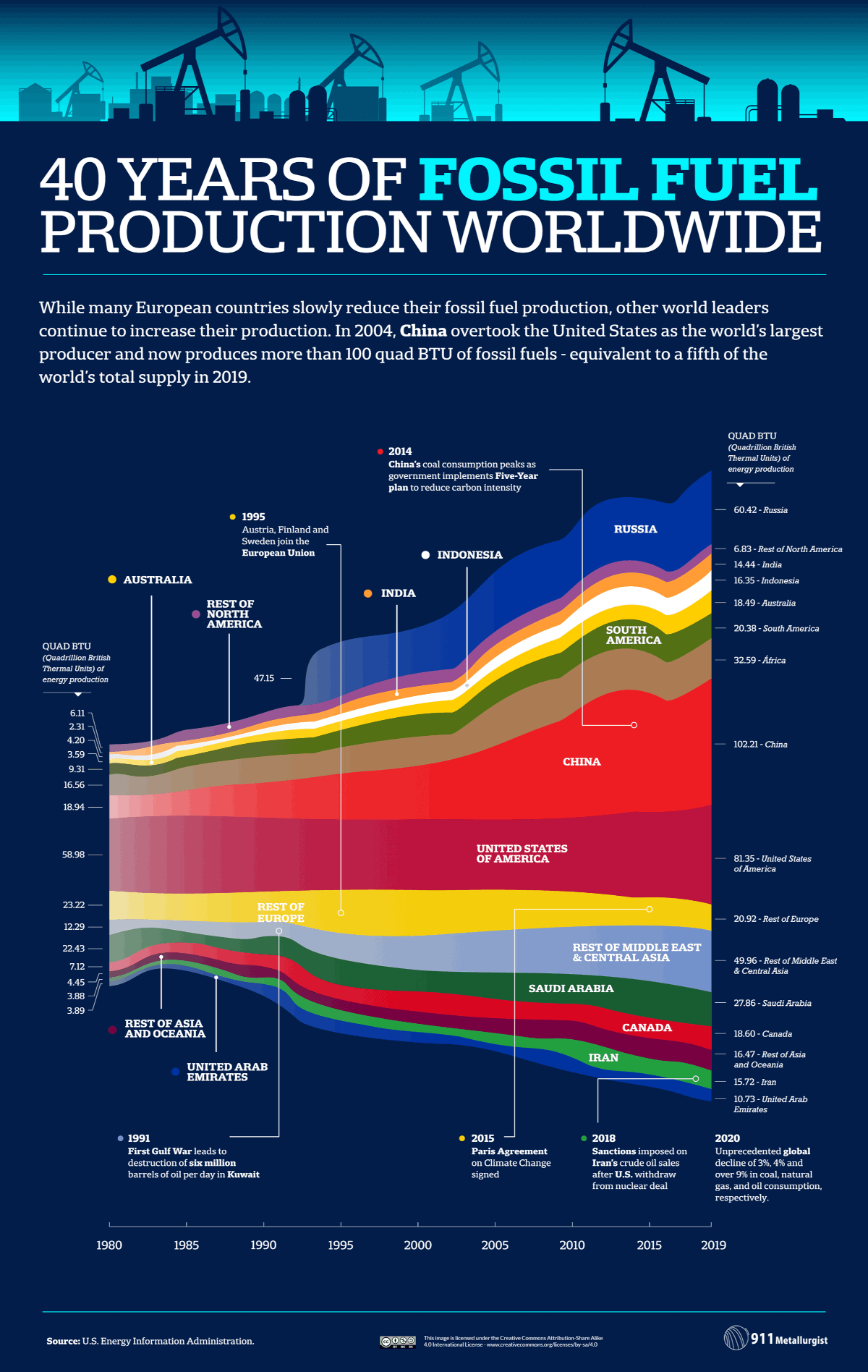

In 2015, we warned that corporate sovereignty would threaten EU plans to protect the environment in the TAFTA/TTIP trade deal between the US and the EU. TAFTA/TTIP never happened, but fossil fuel companies were able to to use other treaties to demand over $18 billion as “compensation” for the potential loss of future profits as the result of increasing government action to tackle climate change.

Chief among those treaties with corporate sovereignty provisions was the Energy Charter Treaty (ECT), which is designed to protect investments in the energy sector. Research by the International Institute for Sustainable Development (IISD) shows that the fossil fuel industry accounts for almost 20% of known ISDS cases, making it the most litigious group. Recently there has been a wave of corporate sovereignty cases brought by fossil fuel companies, with most settled in their favor. The average amount awarded was over $600 million, almost five times the amount given in non-fossil fuel cases.

It has become clear that corporate sovereignty represents a serious threat to countries’ plans to tackle the climate crisis. The obvious solution is simply to withdraw from the ECT, but there’s a problem. Article 47 of the treaty states:

The provisions of this Treaty shall continue to apply to Investments made in the Area of a Contracting Party by Investors of other Contracting Parties or in the Area of other Contracting Parties by Investors of that Contracting Party as of the date when that Contracting Party’s withdrawal from the Treaty takes effect for a period of 20 years from such date.

This “sunset clause” means any of the 53 signatories to the ECT can be sued in the secret ISDS courts for 20 years after withdrawing from the treaty. As a result of this, the EU in particular has been pushing for the ECT to be “modernized”, and recently announced an “agreement in principle” to achieve that. However, it still contains a corporate sovereignty tribunal system:

The modernised ECT will allow the Contracting Parties to exclude new fossil fuel related investments from investment protection and to phase out protection for the already existing investments. This phasing out of protection for fossil fuel investments will take place within a shorter timeframe than in the case of a withdrawal from the ECT, for both existing and new investments: existing fossil fuel investments will be phased out after 10 years under modernised rules (instead of 20 years under current rules) and new investment in fossil fuels will be excluded after 9 months.

Countries that later withdraw from the modernized ECT can be sued for 10 years, rather than the current 20 years. Several EU countries have decided that is not good enough, and have announced their intention to withdraw from the treaty immediately, as Politico reports:

Spain, the Netherlands and Poland have all declared their intention to exit the Energy Charter Treaty (ECT). Italy left in 2015. Germany, France and Belgium are examining their options, officials from those countries said.

France has confirmed that it will be pulling out, as has Belgium. For those countries that leave before the “modernized” ECT comes into force, companies can potentially use the sunset clause to sue them during the full 20 years afterwards. The only solution that addresses the serious threat of corporate sovereignty is to remove the sunset clause completely from the ECT. According to one analysis from the IISD, that’s possible if a group of ECT’s contracting parties agree to the move amongst themselves (“inter se”) as part of a joint withdrawal:

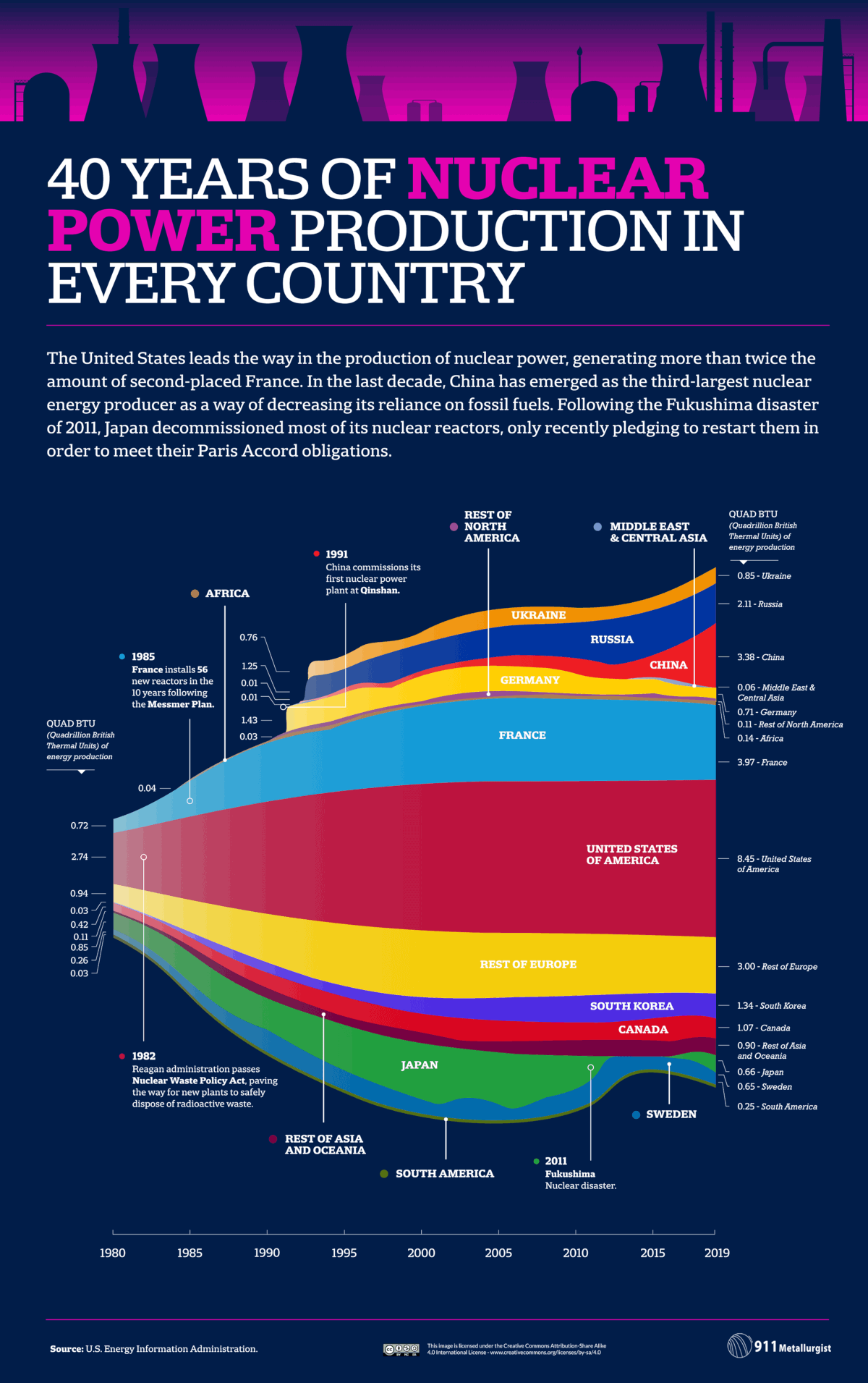

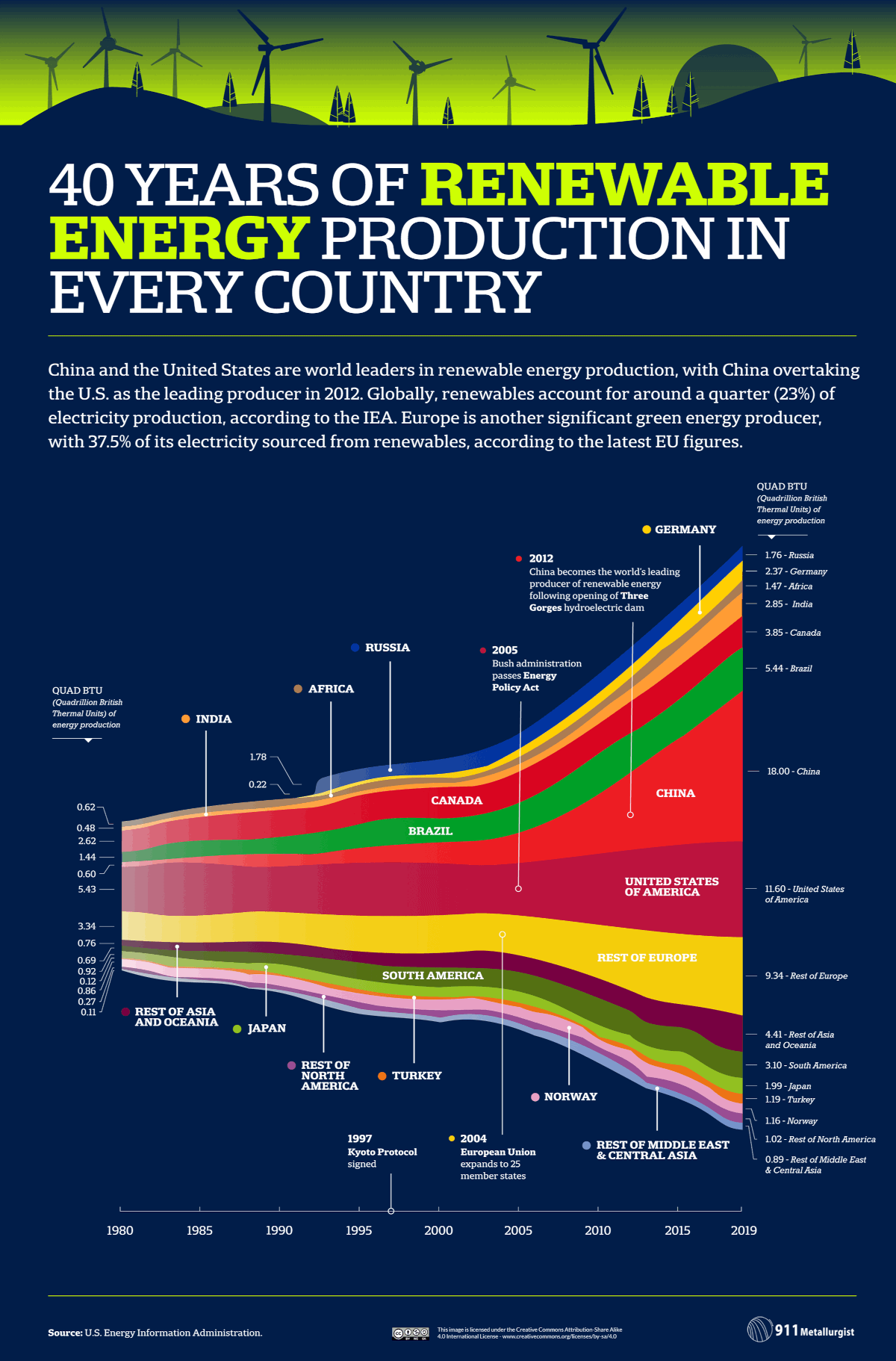

There is a legal basis for a withdrawal from the ECT with an inter se neutralization of the survival clause. In contrast to the continued protection of existing and certain future fossil fuel investments under the EU’s amendment proposal, such a withdrawal would put an immediate end to treaty-based fossil fuel protection and ISDS among all withdrawing states. In the short term, this would significantly reduce ISDS risks, given that 60% of the cases based on the ECT are intra-EU. It would also enable the EU and its member states to comply with the EU’s climate objectives and EU law. If further contracting states were to join, the ISDS risk to strong climate action would be further reduced and could pave the way for a fresh, unencumbered negotiation of a truly modern energy treaty that would support the expedited phase-out from fossil fuels and the transition to renewable energy.

It’s an imperfect solution, but better than the half-hearted “modernized” ECT proposed by the EU. The current mess shows that the issue should have been addressed ten years ago, when the problems of the “lurking monster” of corporate sovereignty first became apparent.

Source: Finally: Countries Start To Rebel Against Corporate Sovereignty, But Ten Years Too Late | Techdirt